|

Installation

The requirements of the site for placing ZHM series grinding mill

1.1. The unit should be located in a laboratory or clean industrial environment. Never place

the unit in a location where excessive heat, moisture, or corrosive materials are present.

1.2. Ample room, such as one meter around the machine, is required for maintenance. The

machine should rest on a level and flat surface such that it will support the unit without

shaking.

1.3. Ambient temperature 10~40℃.

2.1. 380V / 50Hz, 3-phase+earth.

2.2. Power supply lead section≥ 1.5mm2, earth lead section≥ 1mm2.

2.3. For power supply, fluctuation of voltage ≤10%, fluctuation of frequency ≤0.5%,

grounding resistance of ground wire ≤10Ω.

CAUTION! The protective ground wire must be installed.

2.4. The length of unit power cable is 3 meters.

CAUTION! Before installation of the power cable, be sure the Breaker is OFF.

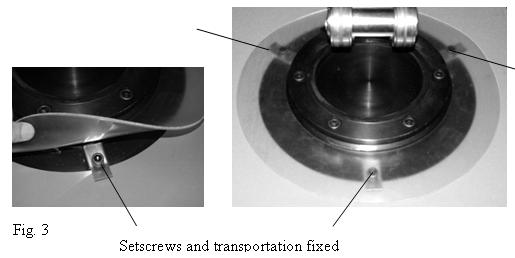

3. Remove the setscrews

CAUTION! Remove the setscrews and take out transportation fixed (3 sets).

Adjust foot; enable the equipment stably not to rock

Operating instruction

In has not vessel or vessel had not in tight situation, cannot starting equipment.

1. Fill sample

Fill sample in vessel 30~80 grams. Vessel locates on the plate tight.

CAUTION!Vessel will fail if fill sample in mill box is ≤10 gram .

2. Set time

There are three steps, Hour step (H), Minute step (M) and Second step (S), in the timer. The

value of the timer expresses running time, two- digit integer ahead of letters and two- digit

decimal place behind the letters. Setting time within 3 minutes for Tungsten Carbide vessel and

within 10 minutes for Chrome-Steel vessel is normal.

1. Put the vessel with the sample charged into the fixture of machine. Depress the handle to

position. Put on the cover to position. Push the green bottom to start.

2. In the event of abnormal operation, immediately push the red bottom . Do not open the cover

until the machine fully stops.

3. Open the cover; take out the vessel . Put the discharging sample into the sieve, to make

sure the granularity of 80% discharging sample ≤ 80um.

4. If the sample does not come up to requirement, take the vessel out and allow it to cool down

for 10~20 minutes, then operate again, confirming the best mill time.

5. For the first time, remove the cover of electric control box , push the startup button,

observe motor protector: When the motor is running, the A-phase, B-phase,C-phase indicators

will light; overload does not light. This is normal.

Maintenance instructions

To ensure that the sampling is of highest quality, the vessel must be cleaned after every use.

Use 3~5 drops of lubricant in Oiling nozzle of eccentric and Oiling nozzle of swing stick

once three month. Lubricant is L-CKE.

|