|

-----------------Water Chiller Details----------------

Water chillers provide constant temperature water for equipment.Water chiller working principle

is to move equipment’s heat emission to chiller’s water tank passes the medium-Water; Heat

stored in water tank passes the medium -- Refrigerant, replaces to the condenser of the water

chiller. Heat stored in condenser will taken way by rotating fan (air-cooling type) or

transferred in to the cooling water (water-cooling type).

The choice of water chiller

Cooling Capacity

For normal operation of the equipment, please choose right type water chiller (cooling capacity

is over 120% of equipment’s heat emission).

Cooling capacity of water chillers made by ZHONGHE range from 300W to 300KW, general types are:

300W, 500W, 1KW, 2KW,5KW,8KW,12KW, etc.

Temperature Stability

For the normal operation of the equipment, please choose Temperature stability of the water

chiller, usually, equal to or above the stability requested by the equipment.

The stability of water chillers made by ZHONGHE ranges from ± 0.1℃ ~± 2℃, the general

specifications are

Type B (upper & lower limit): ±2℃,

Type R (Hot Vapor Bypass): ±0.5℃, ±1℃

Type H (high precision): ±0.1℃( the cooling capacity is higher than 5KW),

Temperature Rang

For the normal operation of the equipment, please choose temperature control range, usually

equal to or above the temperature control range the equipment requested.

Temperature control range of water chillers made by ZHONGHE is between ﹣20℃ ~﹢35℃, general

specifications are: ﹣20℃ ~0℃,﹣5℃ ~+10℃, +10℃ ~+35℃.

Types of water chiller

Types of water chiller made by ZHONGHE are: divided type, integrated air-cooling type, and

integrated water-cooling type. Buyers may choose from those threes types according to their

installation condition.

1) Features of divided-type are: the indoor unit is small, low noise and little heat emission;

but the installation must be operated by professional workers, and there should be suitable

installing place for outdoor unit, the installation can not be moved.

It is applied to situation which owns the space to install outdoor unit of the water chiller.

2) Features of integrated air-cooling unit are: the installation is no need to be operated by

professional worker, and the unit is removable after installation. However, the unit is larger

than the divided type, its noise is higher and it emits heat, if the cooling capacity of water

chiller is higher than 5KW, it should be placed in a single room.

It is applied to situation which places in a single room, or cooling capacity of small water

chiller is lower than 2KW

3) Features of integrated water-refrigerated unit are: the installation is no need to be

operated by professional worker, the unit is removable after installation, the unit is small,

emits no heat and low noise; however It must connect external cooling water and the sewer or

return pipe.

It is applied to situation which dissatisfy the installation condition of air-cooling type, be

allowed to pour water, or own circulating water resource. for instance Clean Room.

-----------------Press machine Details------------------

The XRF is one relativity analysis method, unknown sample have to the standard sample the same

density distribution which the calibrations curve uses. XRF analysis requests the compression

pressure of samples and compression process is fully consistent. The ZHY series Press Machine

is the ancillary equipment for XRF.

The choice of press machine

The automatic presser has a pressure transducer and automatic hydraulic pressure system which

adopts the program system (PLC) for exact control. According to the preset program and the

signal sent by the press transducer, the presser may control the pressing procedure exactly;

furthermore, the operation state can be presented all the time. After choosing the pressing

style, we only need press one button to start and over the whole pressing procedure

automatically. The pressing quality could be assured without concerning the operation.

Manual presser has pressure transducer and pressure meter. The pressing is finished by hand,

the read of pressure meter need to be checked for special operator. In addition, the pressing

quality is influenced by the experience of operator. The consistence of the quality is hard to

keep.

The highest pressure

According to the demand of the pressing of different material, various

pressure need to be

chosen. The proper pressure is between the 20%~80% of the highest pressure. For example, if the

pressing asked for 300KN, ZHY-401 is appropriate, if the demanding pressure is about 400KN,

ZHY-601A press machine could be used.

Choice of vessel

The ZHY series’ press machine, with integrated mold pressuring technology, is applied for

boric acid, steel ring, aluminum cup, plastic ring and low-pressure polythene pressuring.

Choice vessel mainly decided by the using habits or industry standards. Cost of boric acid is

lower, so it is applied most widely. Plastic ring can be easily used; steel ring is most

durable and the first to be applied for presser. Fewer users adopt aluminum cups, and low-

pressure polythene because they are for special sample pressing.

Special design

1)Automatic slow-pressurization: push “Start” button, the press head will move upward quickly

towards the sample, and as the space between the press head and sample decreases, the press

slows down and begins slow pressurization until it achieves the set upper limit. This process

causes the air to be removed and the compression of the sample to be even thus enhancing the

overall quality of the sample.

2)Automatic slow-decompression: when the pressure-holding episode is completed, the press

begins slowly releasing pressure as the press head moves downward automatically. (For during

the pressing procedure, vacuum forms between the press head and the sample, if the pressure is

removed suddenly, the fast downward press head may deform the pressed sample.) After the press

head is out of contact with the sample, the head falls quickly, providing an efficient means of

production.

---------------Grinding Mill Details------------------

The XRF is one relativity analysis method, unknown sample have to the standard sample same

grain-size distribution which the calibrations curve uses. XRF analysis requests the sample

powder to have the extremely fine degree and homogeneous degree.

The ZHM series Grinding Mill is the ancillary equipment for XRF, satisfy these two requests.

The ZHM rotational speed the choice

1)1400r/min grinding mill is high grinding efficiency; as well as higher decibel noise and

faster speed of temperature rising of the vessel during the grinding process.

2) 910r/min grinding mill is efficiency is lower somewhat low, lower decibel noise, slower

speed of temperature rising of the vessel and the capacity of producing the same standardized

grinding quality.

3) ZHM-1-250, ZHM-3B are designed for industrial manufacture; ZHM-3B is designed for grind

large quantity sample.

4) ZHM-1V and ZHM-1T are designed for experimental purpose—laboratory. Some sample chemical

properties change after the temperature rises, so you need to choose ZHM-1V, or ZHM-1T.

5) ZHM-1V has the device of frequency change according to customer’s various demands.

Charging granularity:This is the size of the input samples (before grinding).

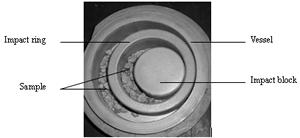

Vessel includes vessel body, impact ring, and impact block. The sample places between them, the

sample diameter is most greatly 5mm

Discharging granularity: This is the result of output samples (after grind)

Discharging granularity is the sample diameter after grinding.

Fill sample

Vessel the most used of goods shipped quantity is 100cc.

We recommend you to fill 20~40 gram sample once.

Choose proper vessel: (Tungsten Carbide, Chrome-Steel, and Manganese-Steel)

Firstly the rigidity of the sample should be taken into consideration; the vessel should be

harder than the sample. If you deal with fast and intense grinding, you may choose tungsten

carbide vessel; the second factor is the influence of the material to the analysis. Tungsten

carbide can be used while the inspect of the sample should not be affected by the existence of

element of carbon, tungsten or cobalt; Chrome steel vessel can be used while the inspection of

sample may not be affected by the appearance of iron or chromium element; Manganese steel

vessel can be used when the inspection will not be affected by the presence of iron or

manganese element.

Vessel amount

If you are only a sample measurement, and very few samples, a vessel is enough, if you are

measuring two or more samples, or sample volume for a long time, a vessel is not enough.

After grinding the first kind of sample, you need to carefully clean-up vessel, or else there

will be remnants of the sample, when you are grinding the second sample, the first sample will

pollute the second sample, and will affect XRF the analysis result.

In addition, vessel in the grinding will heat, if you measured the amount of samples for a long

time, vessel of the temperature rise, the sample will stick in the vessel wall, the impact on

the quality of grinding. Then you need to wait for the vessel's temperature dropped to below 50

℃, and then grinding of samples. Our customers tend to buy more than a few vessels.

|